Welding requires some skills. I suggest you take a look at the following video: Link

When operating the soldering iron, please pay attention to the high temperature and don’t hurt yourself

High temperature of the soldering iron may damage the control board. Please ensure that the soldering iron does not heat the control board for more than 3 seconds

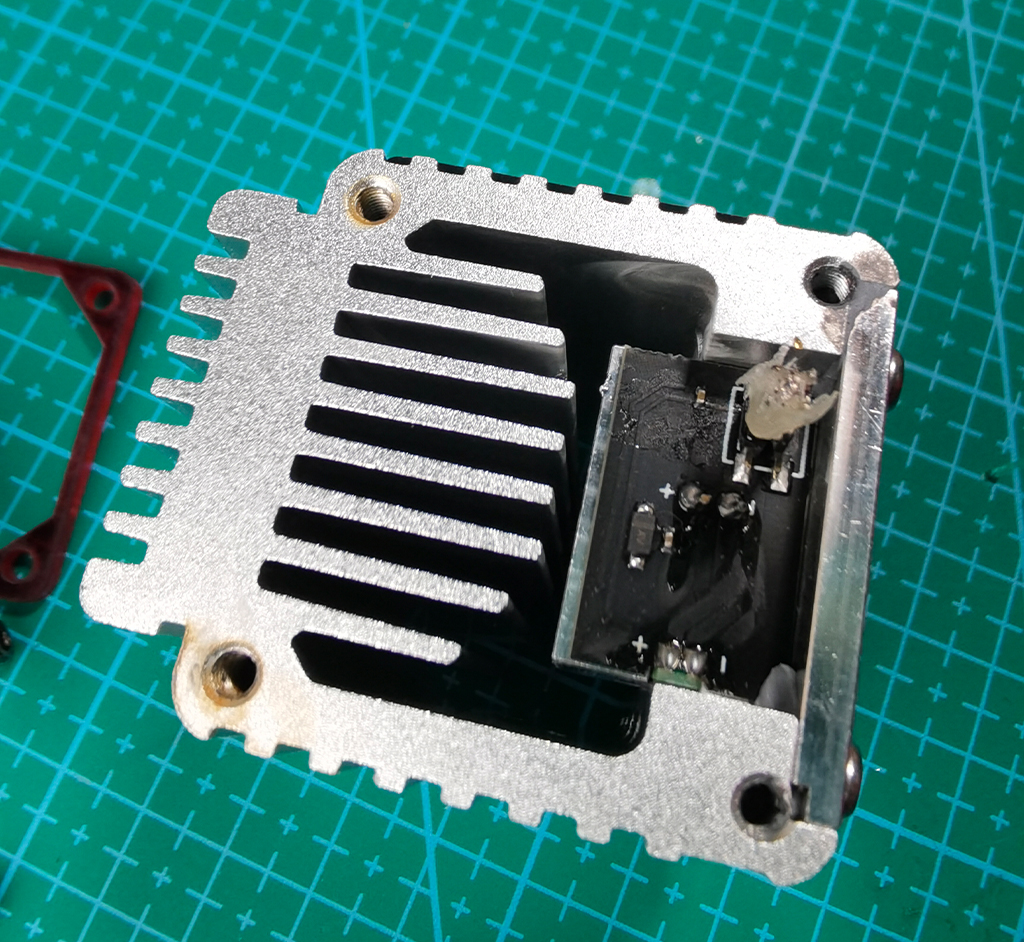

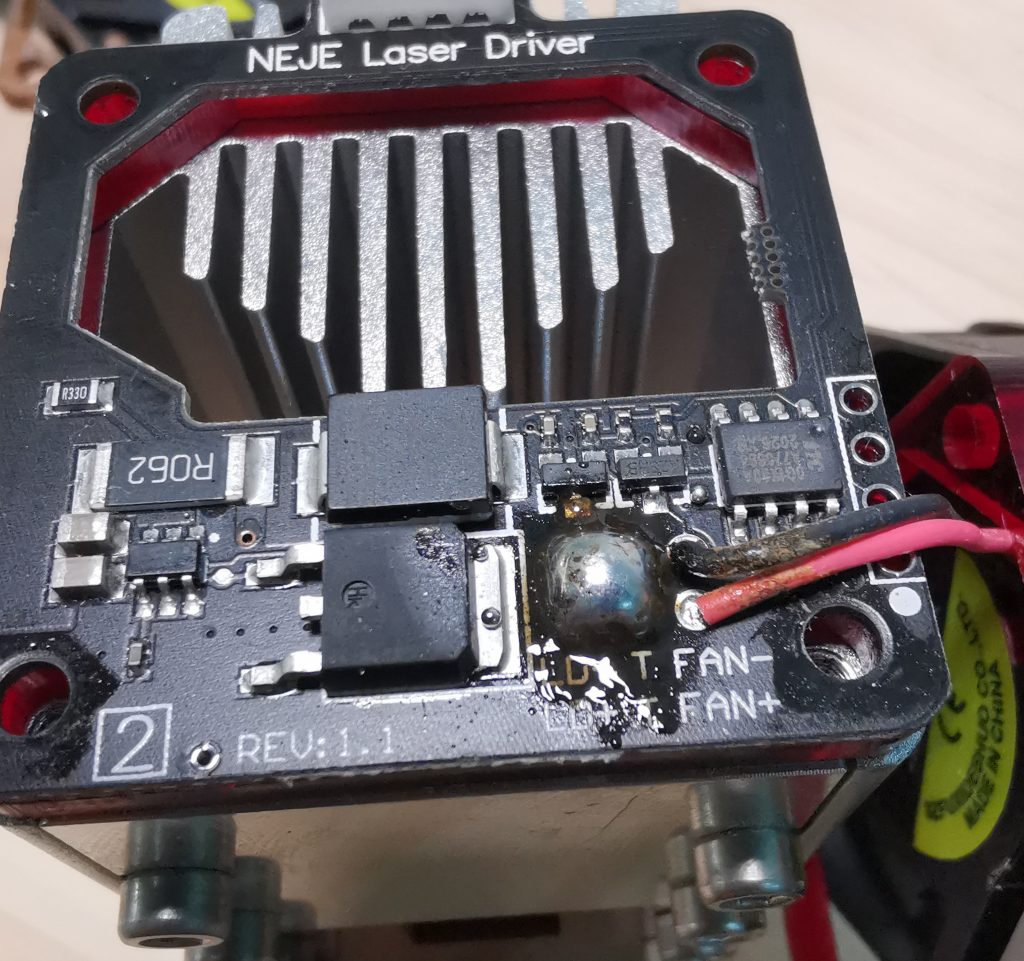

Check out what you got :

- A driver board with a fan on it

- Flux (help with welding)

- A piece of solder

- 12V Soldering Iron

You may receive a bottom board(small) and a PCB like stick. Please ignore it. They are useless when changing the drive.

How to change control board for laser module?

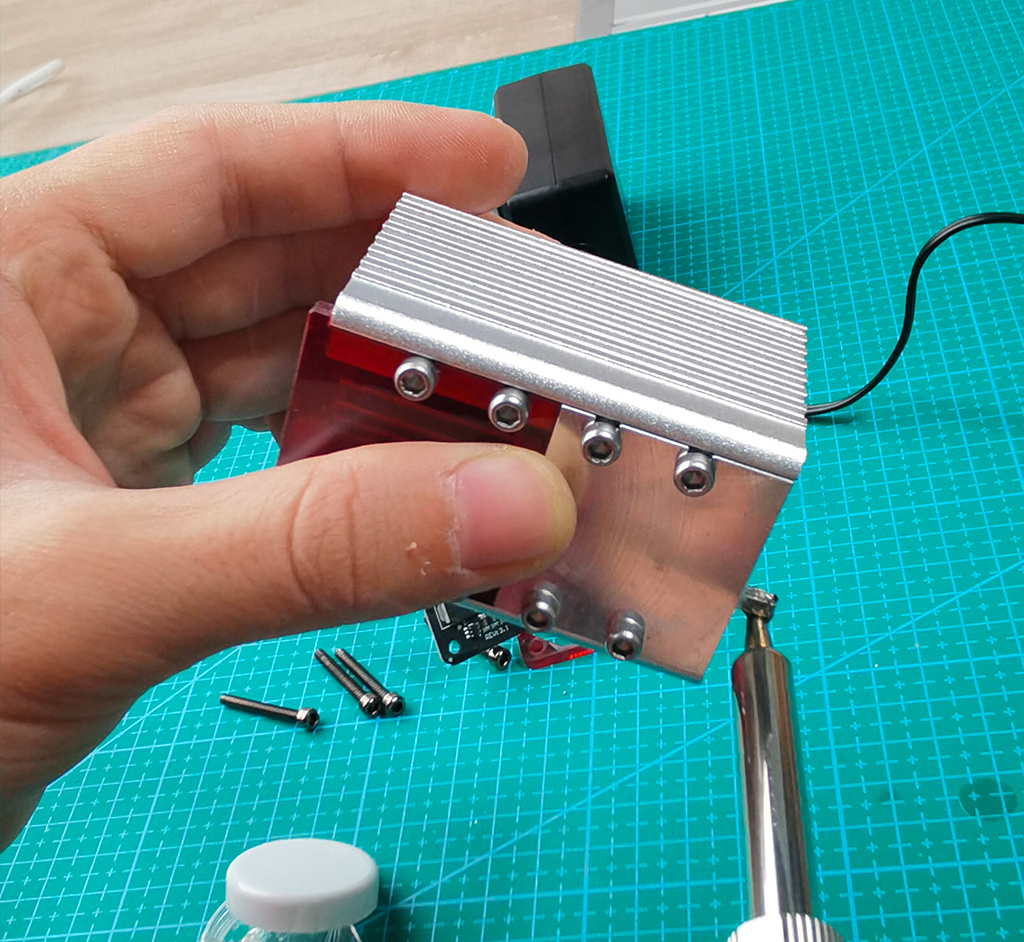

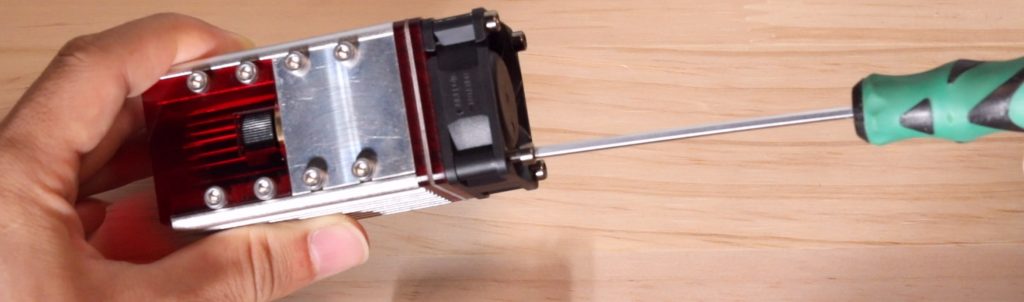

First, disassemble your laser drive and heat up your iron(may take 3 minutes)

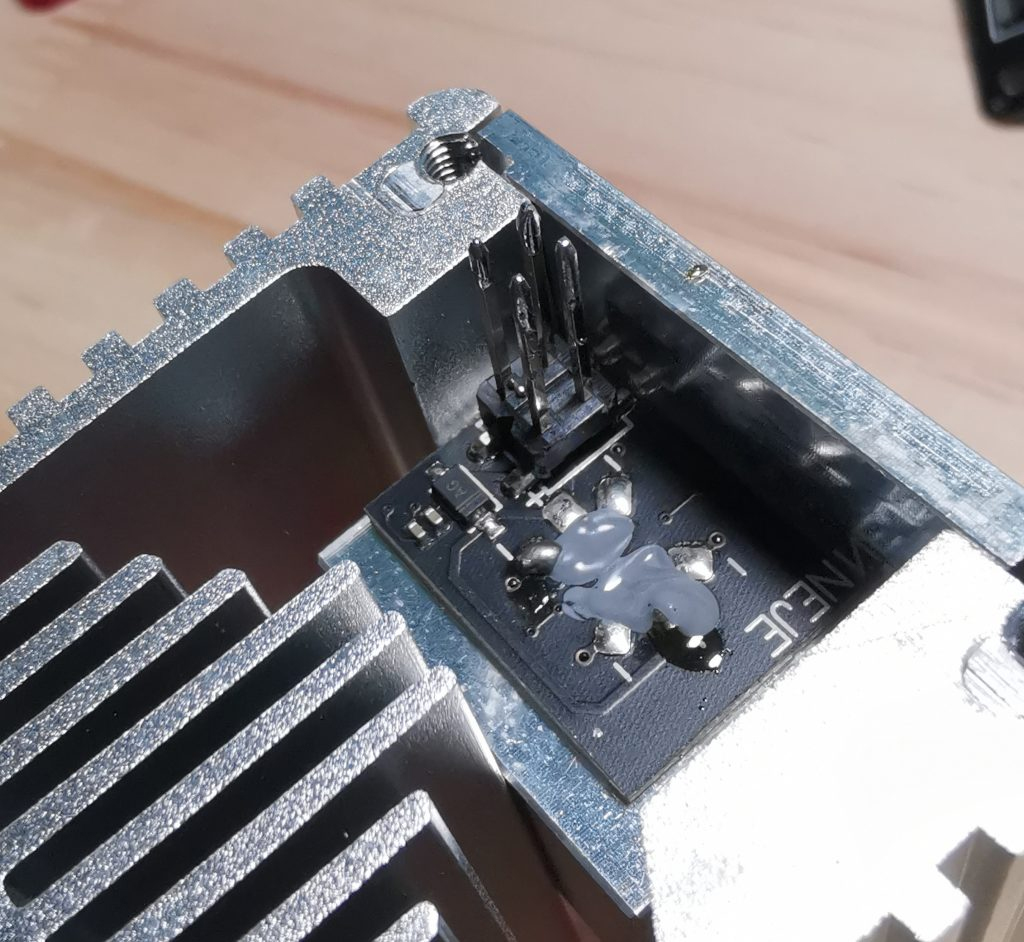

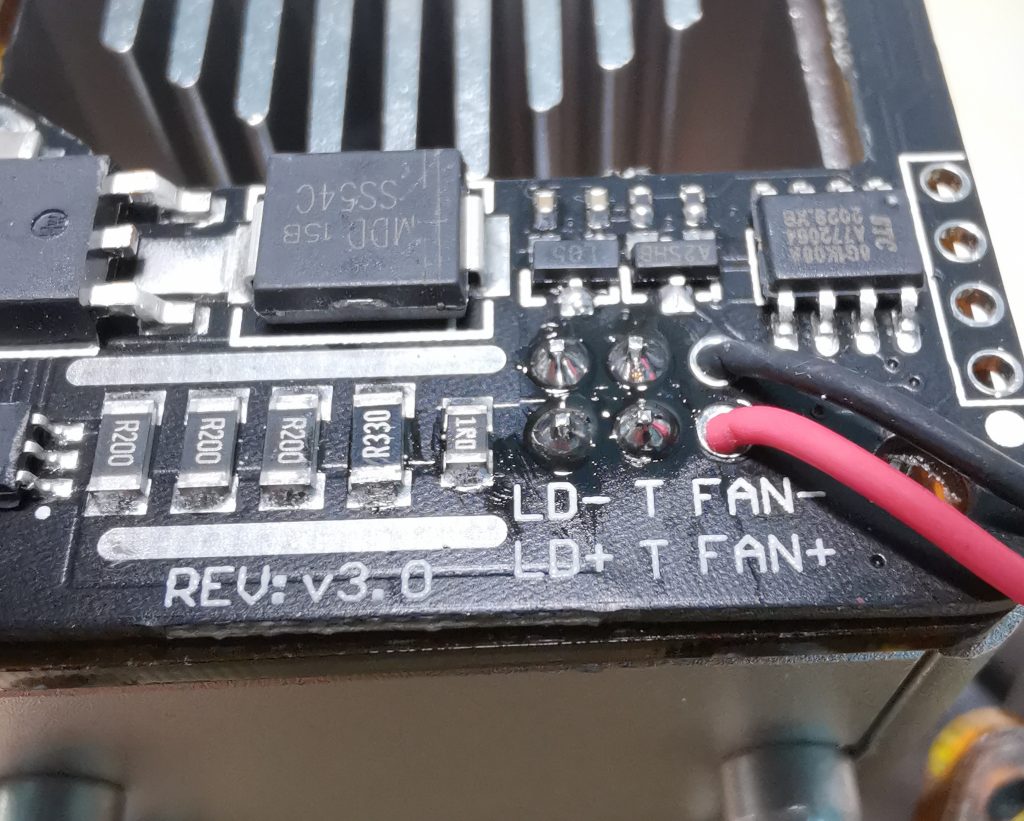

Add enough solder to make all 4 pins have solder, as shown in the figure below:

Heat the four points at the same time, and gently lift the control board with your left hand. If the method is correct, you can quickly separate the drive board and the main body(If you find it difficult to remove, try applying some flux to the soldering area)

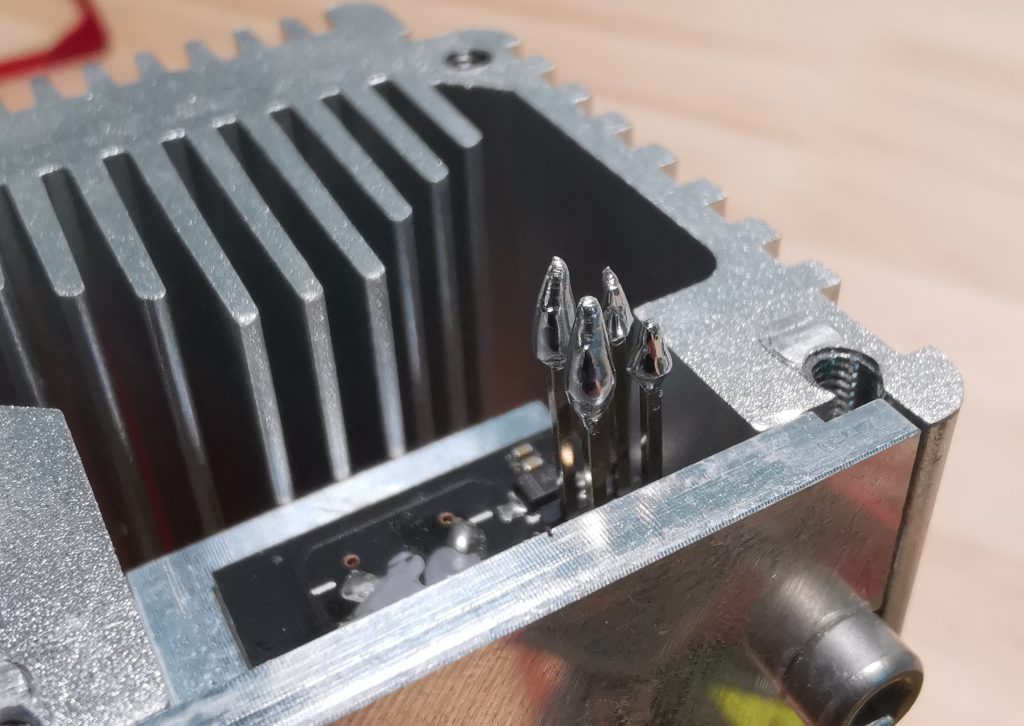

When you successfully remove the driver board, a lot of solder may remain on the pins. You need to clean them.

How to clean the pins?

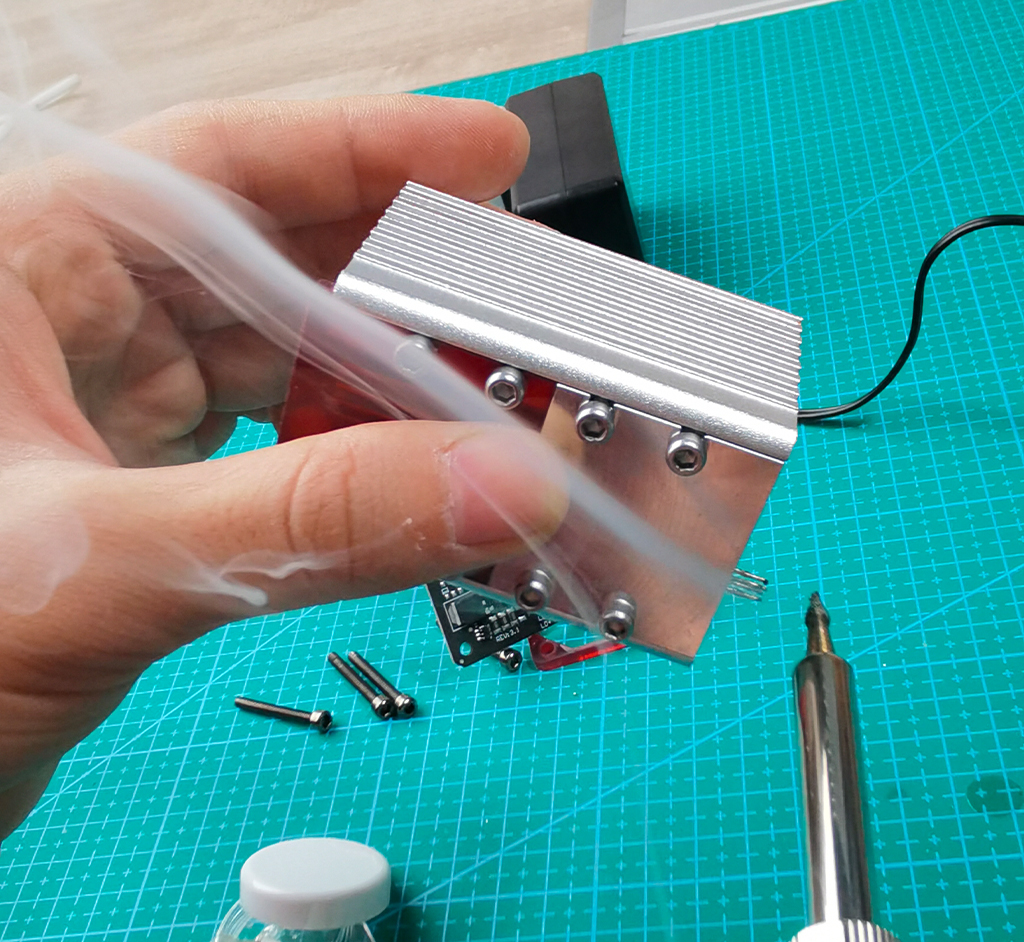

Step 1: Apply the flux to pins (Click on image to enlarge image)

Step 2: Tilt your laser module down, touch the soldering iron to the pins(make sure your iron is clean, clean it with napkin)

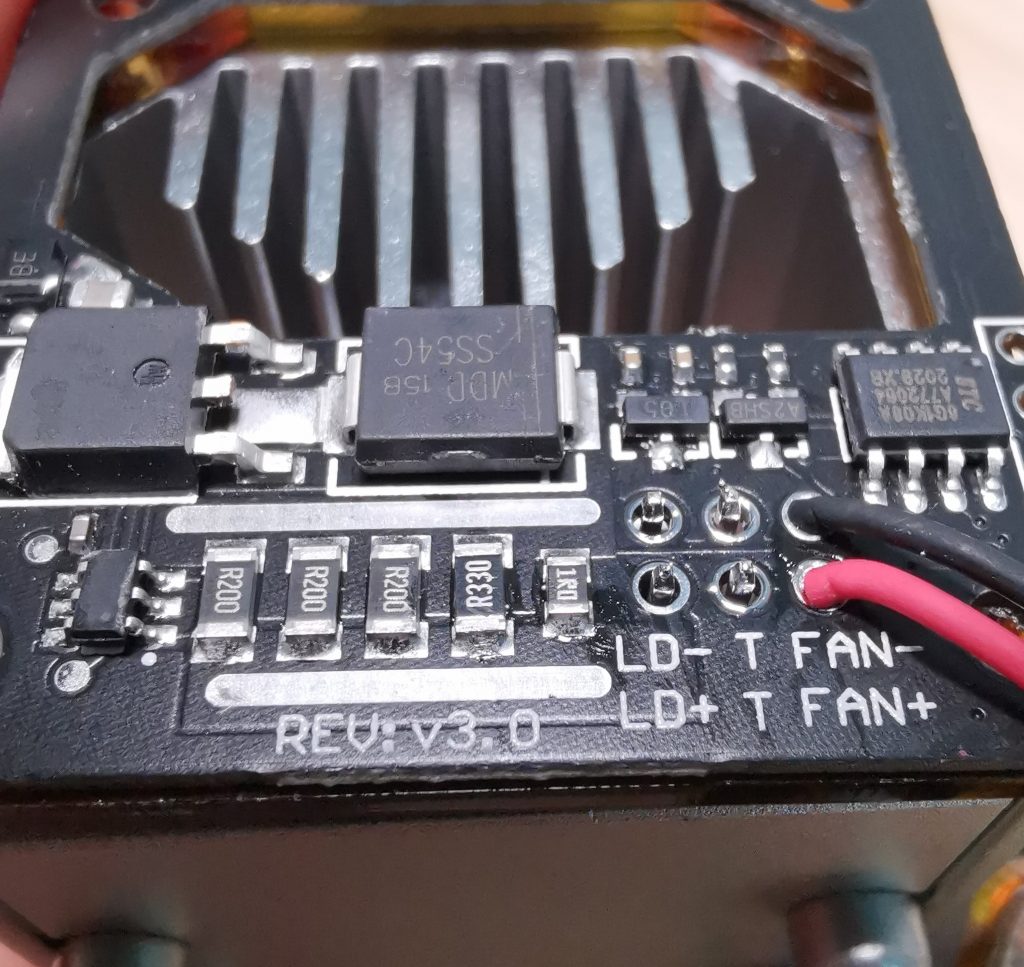

Put on new control board:

Welding new drives:

This is a video show how to change control board for N40630/A40640: