There are two types of belt problems, too loose or too tight

Too tight

- Will cause stepper missing steps

- Will cause stuck somewhere

- Will cause failed at motor test

Too loose

How to judge my belt is too tight ?

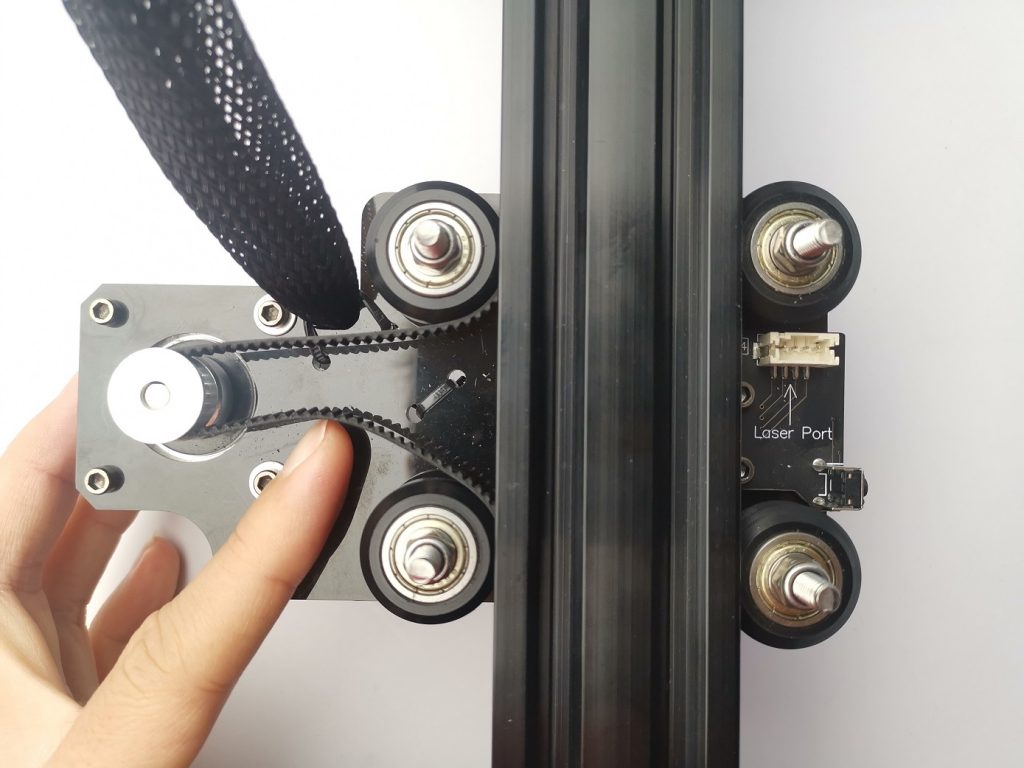

Disconnect the wires from the motor first (this is important) and try moving the axis back and forth by hand, it shouldn’t be a lot of effort, for the X axis you should be able to move with one of your pinky fingers, otherwise consider the possibility of belt too tight, and the resistance should be uniform throughout the entire stroke, there will be no sudden increase in some place, otherwise, consider the possibility of belt too tight.

ow to judge my belt is too loose ?

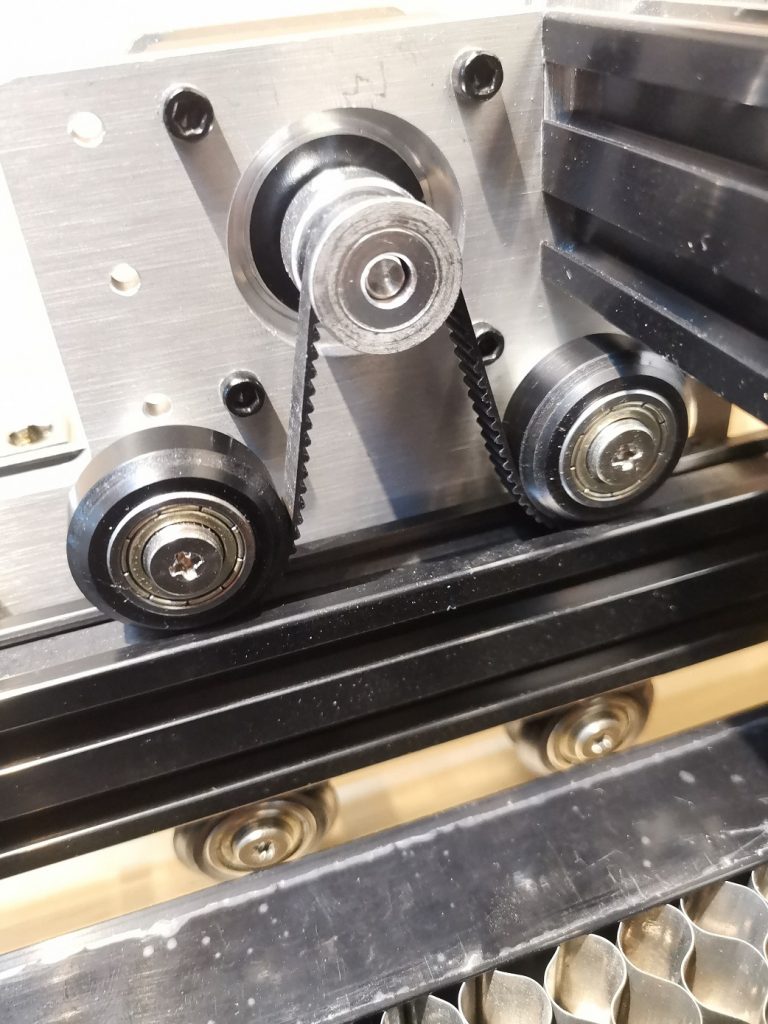

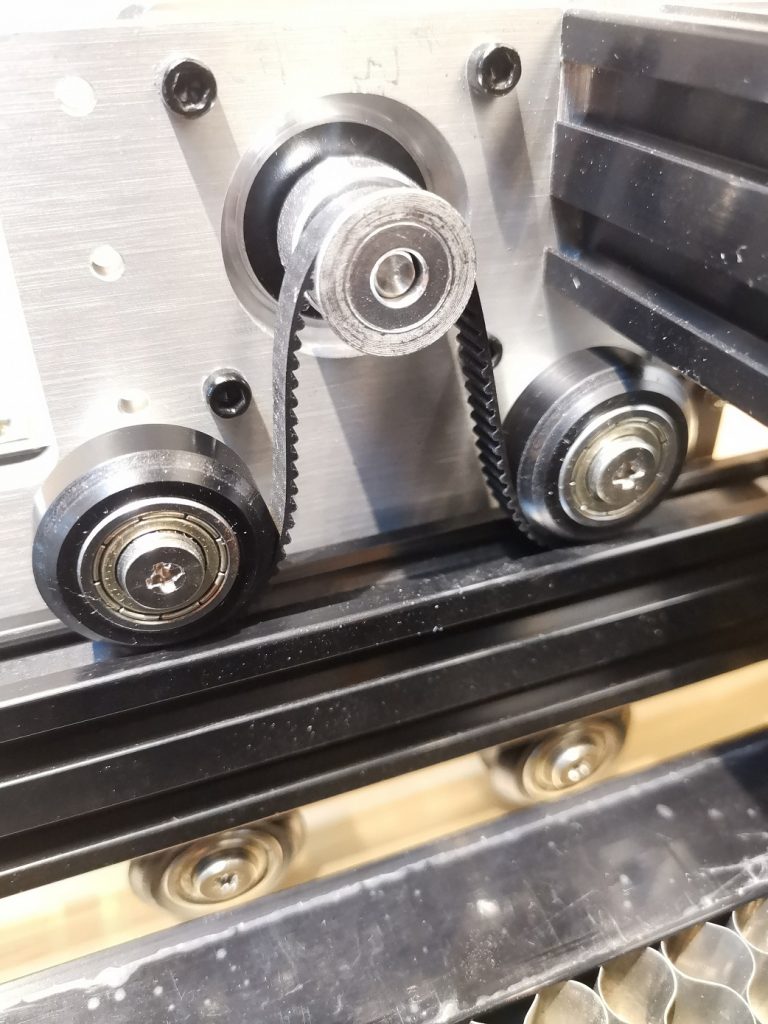

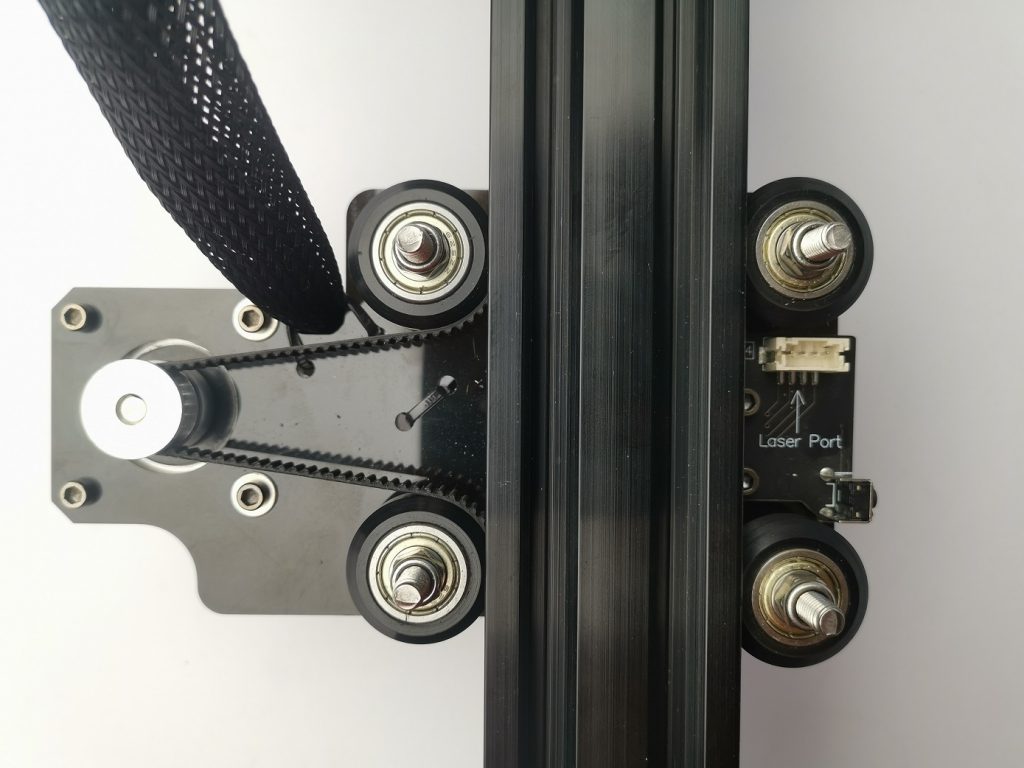

Look for a triangular area on your device similar to the image below (Click on image to see larger image)

For Max and Pro series devices, you need to check 3 belts, 1 on the X axis and 2 for each of the Y axes

How to adjust belt?

For NEJE 1/2/2S Plus

No adjustment is required for the X-axis of the 2/2S Plus device, because it is a fixed-length belt

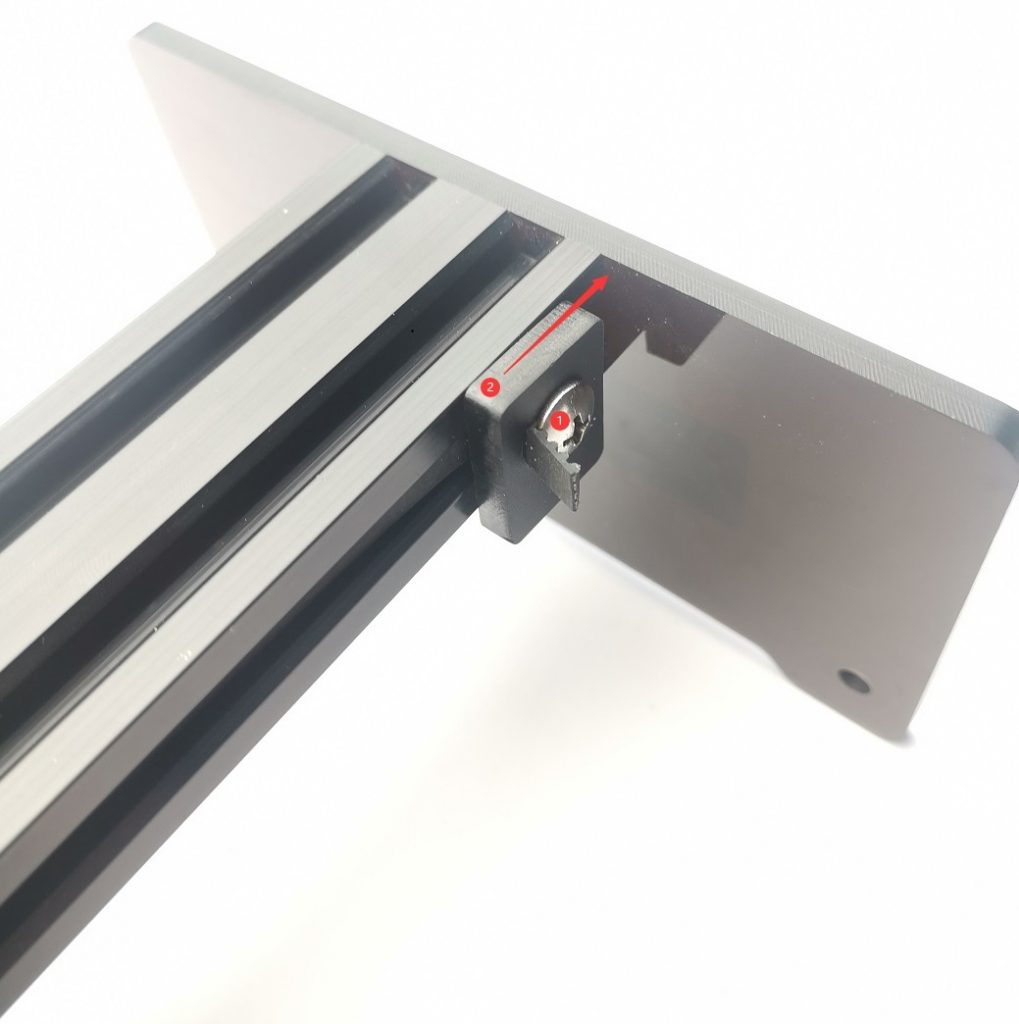

Look for this location on your device, try loosening the screw a bit, then push the slider outwards with your hand while tightening the screw

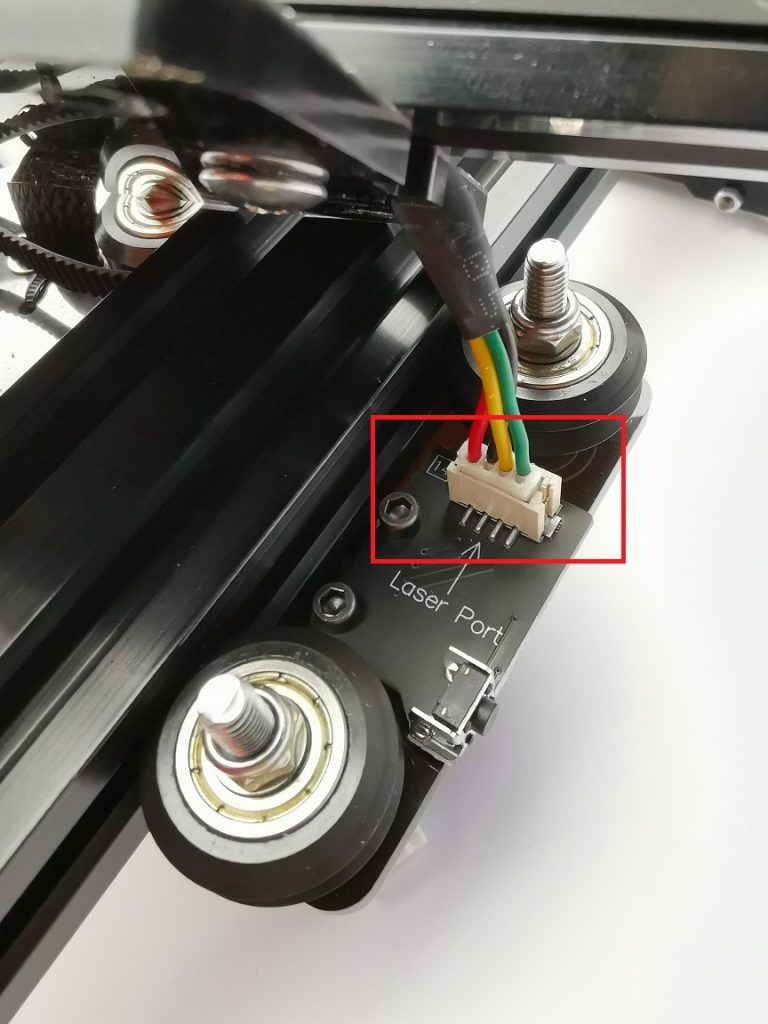

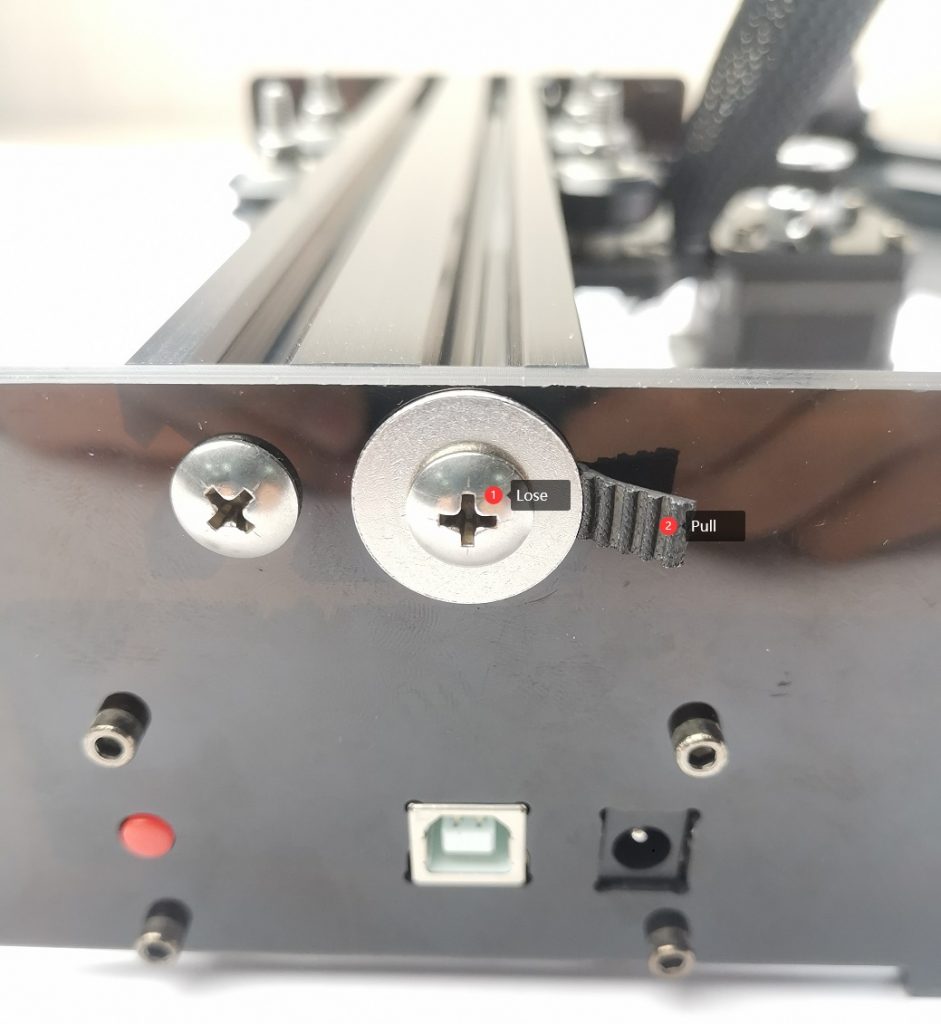

If the slider slides to the top and the belt is still loose, try loosening the screw at this location, then tighten the screw while pulling the belt out

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.